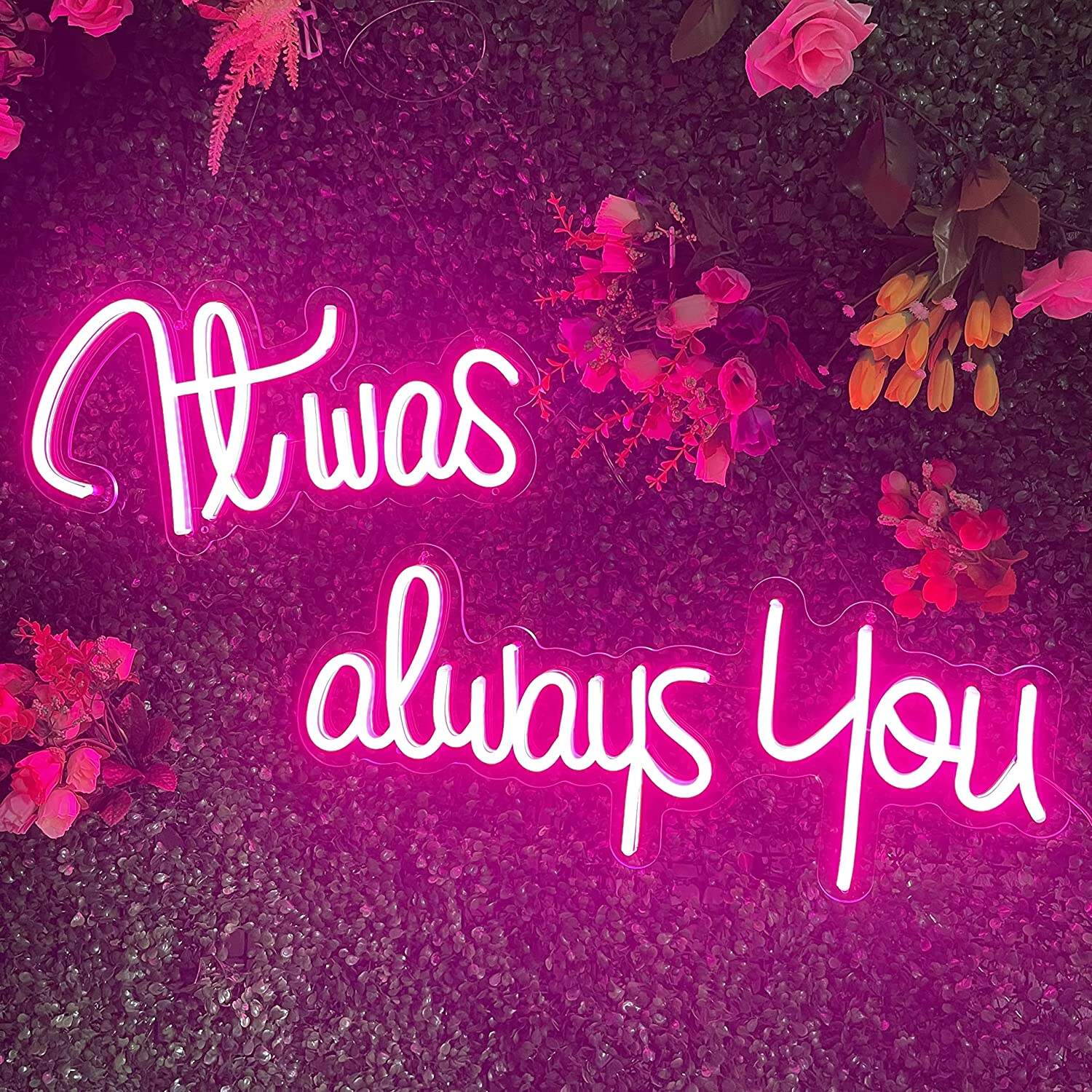

making led neon signs

Making LED neon signs involves a sophisticated blend of modern technology and artistic craftsmanship. These illuminated displays combine flexible LED strips with specialized silicone tubing to create bright, energy-efficient signage that mimics traditional neon's aesthetic appeal. The manufacturing process begins with designing the desired pattern using specialized software, followed by precise CNC routing of acrylic backing materials. High-quality LED strips are carefully arranged and secured to create the desired shape, then encased in UV-resistant silicone tubing that provides protection and diffuses the light evenly. The result is a durable, customizable sign that offers the classic neon look while consuming up to 80% less energy. These signs are particularly versatile, suitable for both indoor and outdoor applications, with the ability to withstand various weather conditions. Modern LED neon signs feature adjustable brightness levels, multiple color options, and can be controlled remotely through smart devices. The manufacturing process ensures superior safety compared to traditional glass neon, eliminating risks associated with fragile materials and harmful gases. These signs are increasingly popular in commercial settings, home decor, and special events, offering a perfect balance of aesthetic appeal and practical functionality.